- company

- global trading

Business Area

- technology

- references

- customer

전체메뉴

Introduction of Michigan Technology

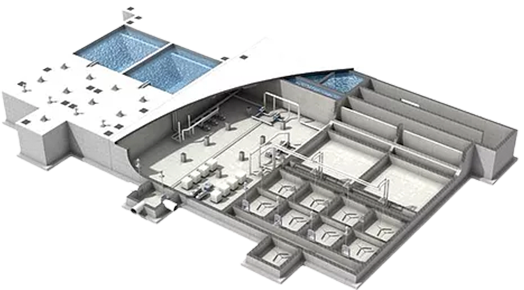

DOF (Dissolved Ozone Flotation) System

Brief Description of the DOF technology

DOF is a single process that combines M-DAF and ozone.

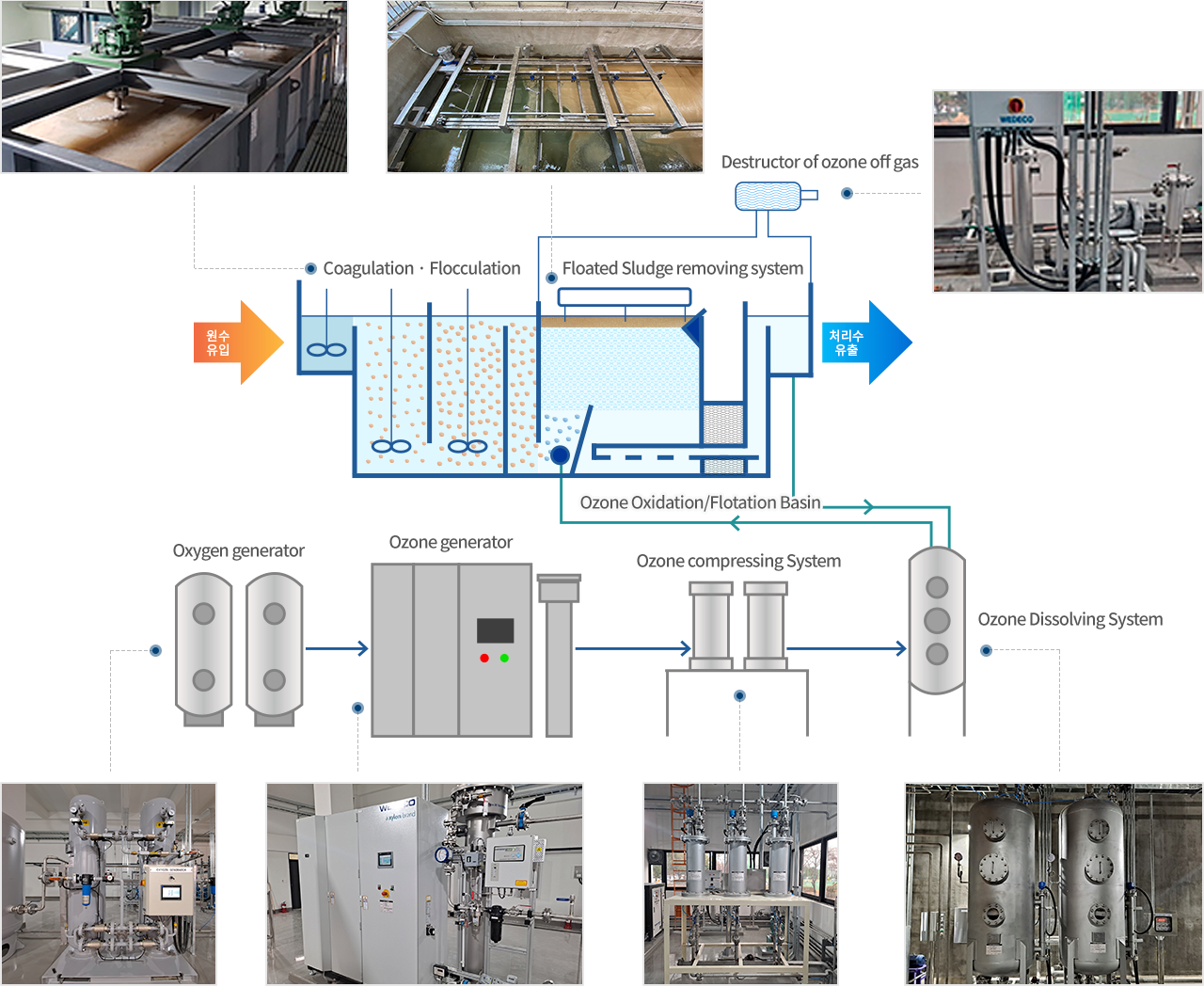

M-DAF removes SS, turbidity, algae, oil, surfactants, and T-P, and ozone removes TOC, BOD, COD, color, odor, taste, and dismfection by-products, agents including virus and bacteria.

Removal of suspended matter, total phosphorus, and algae by flotation method by micro ozone bubbles

M-DOF System

Excellent Separation

Suspended solids, Turbidity,

Oils, Sufactants,

Total phosphorous,

Algae, etc.

Strong Oxidation

Disinfection of Virus, Bacteria

Removal of Color, Odor, Taste

Removal of BOD, COD, TDC, Hazardous Materials

Diagram of M-DOF

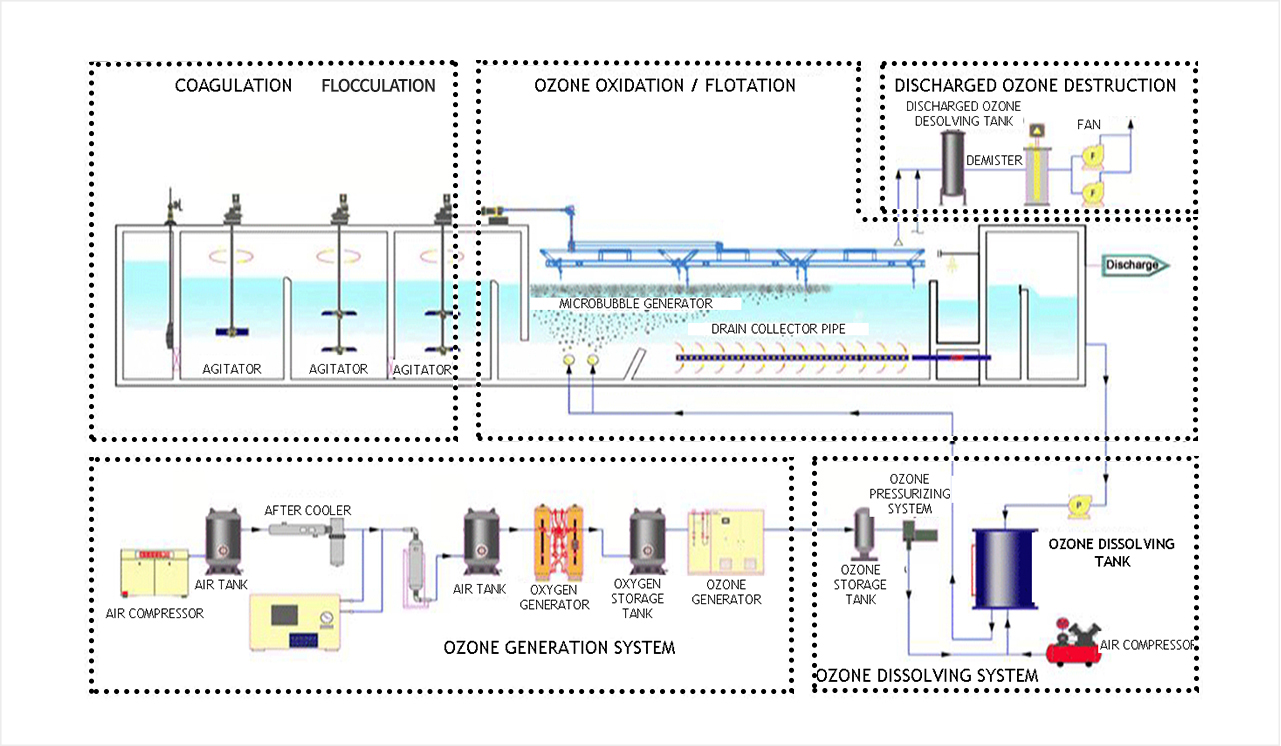

Process Diagram: P&ID

Core Technology

Patented technology that enables to compress strongly oxidative ozone gas into water up to 4 ~ 10kg/cm2, which was applied in M-DAF to generate numerous micro and nano ozone bubbles.

A Micro and Nano Bubble Generating System were developed. The sizes of generated micro and nano bubbles are smaller than 40㎛ and uniform without macro-bubbles, which makes it possible the dense bubble layer.

Hydrodynamic modeling has been conducted in the flotation basin for maintaining high density of bubble layer, which maximizes separation rates of solids and water in the flotation basin.

Advantages of Core Technologies of the DOF system

Contact efficiency of micro and nano bubbles with solids was maximized by maximizing surface area of micro and nano bubbles, which maximizes removal rates of floated flocs.

Minimized hydraulic retention time for reaction, and footprint of the plant by using a unique ozone compressing system of Michigan Technology

Various water quality parameters like SS, oil, surfactant, algae, TP, color, BOD, COD, TOC, and VOCs are removed in a single unit of DOF system

- Simplified System by combining DAF flotation and ozone oxidation processes

- Easy for construction and maintenance of the DOF system by combining two processes which minimizes control points

Quick response for the trouble shooting by accumulated experiences

Minimized Ozone facility by Maximizing ozone utilization rate of up to 98~99% in the DOF system

No need an extra ozone contact chamber and area

Electric power was minimized by minimizing ozone related facilities, and combing two processes

Application Area